Sustainability Series: Plastic

Before you settle into this piece, we highly recommend that you read our Introduction to the Sustainability Series.

Plastic is one of the most polarizing topics in sustainability today, and each year continues to reveal more about its place in the beauty industry. Sustainability is a constantly evolving conversation and the rate at which plastic is produced, used and disposed of has long outpaced the research, technology and innovation needed to understand the consequences of our actions, making it quite challenging to gather data that’s specific to cosmetics. Yet, we do know that the volume of plastic which can accumulate during the process of making a single product is sometimes staggering - if you make cosmetics products for profit and are looking to grow, hardly any brand is exempt from the presence of plastic.

In a roadmap for sustainability released by the United Nations Environment Programme in 2018, the executive summary reads: “The benefits of plastic are undeniable. The material is cheap, lightweight and easy to make. These qualities have led to a boom in the production of plastic over the past century [since the 1950’s]. We are already unable to cope with the amount of plastic waste we generate, unless we rethink the way we manufacture, use and manage plastics. Ultimately, tackling one of the biggest [challenges] of our time will require governments to regulate, businesses to innovate and individuals to act.”

Let’s admit that plastic has gathered a bad reputation - you might even say it’s been demonized in some cases. To be clear, there is no denying that waste is a problem, but to blanket shame plastic without context is to miss an opportunity for a closer look. If you want to dive deeper into all the factors that contribute to plastic waste, take a look at this hugely informative and fascinating collaboration from Oxford University and the Global Change Data Lab:

Particularly in 2020, single use consumption of plastics across multiple industries has seen a massive increase due to essential sanitary and safety precautions needed to manage the spread of COVID-19. It’s important to note that single use plastic is a cornerstone of essential hygiene measures within the medical industry from masks, gloves, gowns and medical instruments. We doubt that we will comprehend the waste consequences of single use plastic throughout 2020 for sometime to come.

As a beauty brand this is undeniably a charged conversation to have, as plastic is dotted across our ‘packaging chain’ and understanding the trade-offs is key. From health effects, to degradation, to ecosystems impact, plastic could easily be a whole PhD dissertation, and it is challenging to limit our focus when this material is a global common denominator of modern consumption. We are attempting to share a simplified perspective on the presence of plastics within the cosmetics industry to better understand the benefits and pitfalls of this material.

We are interested in the life cycle of plastic packaging in cosmetics - more specifically, the contrast between the production of plastic, versus the use of plastic, versus the end-of-life for plastic. As PET (Polyethylene Terephthalate) is the most commonly used plastic in cosmetic packaging and for Josh Rosebrook products, we will be focusing on this material to exemplify the pros and cons of plastic packaging.

Pros of Plastic

Production - It might surprise you to find that Polyethylene Terephthalate (PET) is actually one of the most energy efficient packaging materials to produce. We were shocked too! PET is a thermoplastic with the ability to be heated and formed to make a specific mold shape. PET bottles are usually made from hard or ‘solid-state’ resin using a technique called Injection Stretch Blow Molding (ISBM).

Specializing in life cycle assessment (LCA) and solid waste management, a US independent consulting firm, Franklin Associates, has conducted multiple research studies on PET across various industries. In a 2009 study on the comparison of beverage containers (very similar to cosmetic containers), Franklin Associates found that the production of a PET bottle was far more energy efficient when compared to the production of an aluminium can and glass bottle, respectively. The amount of energy it took to create a PET bottle was 11 million BTU, vs. 16 million BTU for the aluminium can and 26.6 BTU for the glass bottle. The CO2 equivalent (think greenhouse gas emissions) was 1,125 for the PET bottle, 2,766 for the aluminum can, and 4,848 for the glass bottle. When ranking material production in relation to energy efficiency, plastic is second right after wood and aluminum and glass are last. There is conflicting evidence regarding how the world’s oil production contributes to the manufacturing of plastic.

Transport - The weight of goods is an extremely important factor when transporting materials around the globe. From both a cost and transport related emissions perspective, plastic is the preferred choice by ingredient suppliers, manufacturers, and distributors due to a variety of factors. As plastic is more durable there is less chance of breaks, leaks and a stronger resistance to environmental extremes potentially experienced during shipment. For example, if our Hydrating Accelerator were packaged in a glass bottle and shipped from Palm Springs, CA to Toronto, CAN during the colder months, the product would run the risk of freezing, causing the glass to explode. Having to replace any damaged product doubles the carbon footprint of the purchase, on top of both shipments being heavier due to the weight of glass. Additionally, from a consumer experience, traveling with cosmetic plastic packaging is more advantageous - your luggage will be lighter and you don’t run the risk of having smashed glass in your luggage and then having to replace your suitcase, clothing, products etc.

Recyclability - PET and HDPE (another type of thermoplastic) comprise over 96% of the plastic bottle market in the US. PET is the most recycled plastic and the most easy to recycle plastic using mechanical recycling processes such as single stream or multi stream collection. Most US municipalities manage residential recycling primarily via single-stream curbside collection. Single-stream means residents use their recycling bins to co-mingle glass with aluminum and steel cans, various types of plastic, newsprint, junk mail, cardboard, and other paper products. PET is easily identifiable with the recycling code number (look for the recycling triangle with 1 at the center). Thicker resin bottles such as PET are the most likely to be correctly sorted and recycled as opposed to thinner more flexible plastics. The sustainability factor for PET jumps even higher when it gets recycled because 40% of PET’s energy is attributed to its “resource energy” - the energy that can be recaptured and reused through recycling from its raw materials.

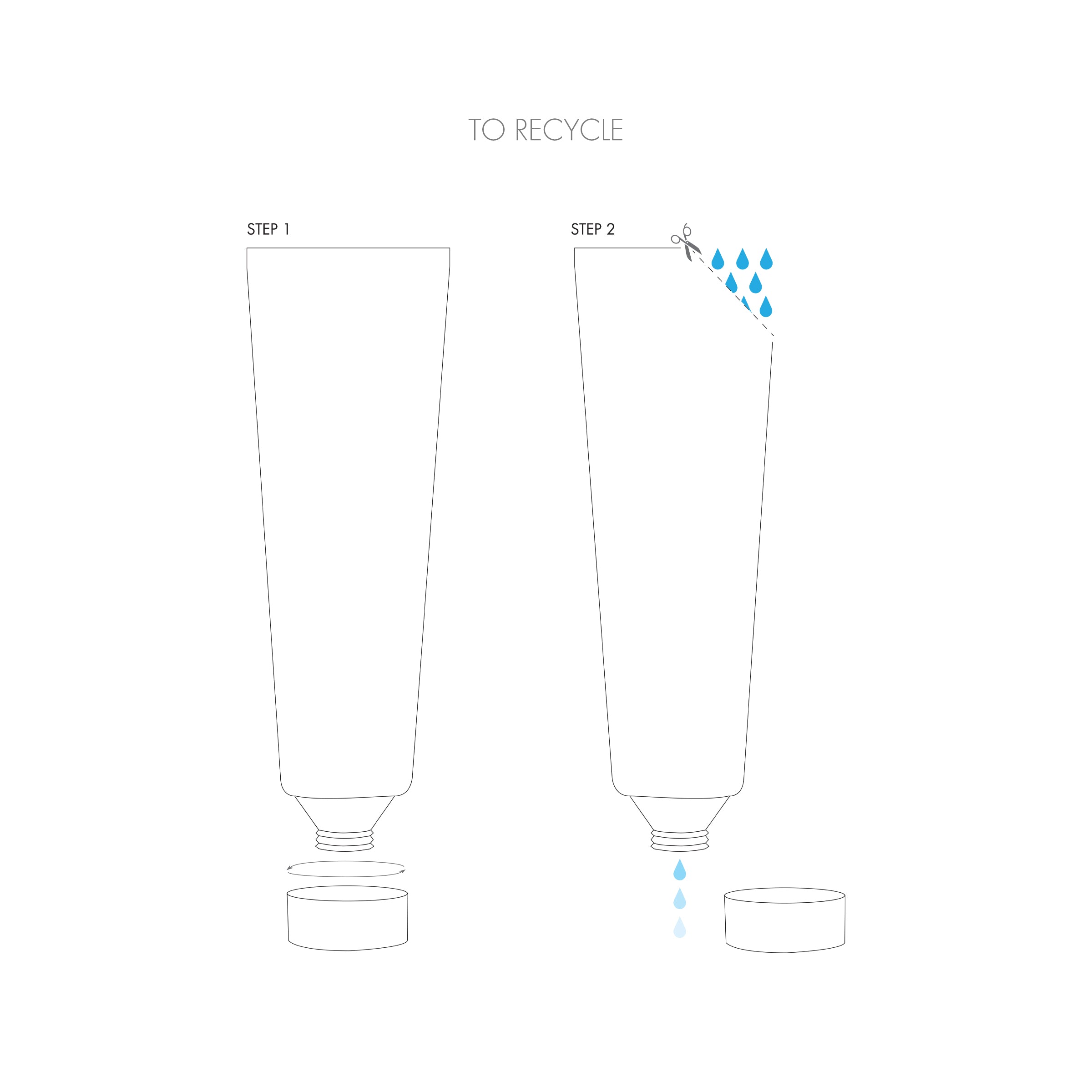

Recycling tip: It’s always good to clean your bottles prior to putting them in the recycling bin for collection.

Multi-use Consumption - This use stands in direct opposition to ‘single-use’ consumption (which will be covered in the cons below). A large majority of finished cosmetic products housed in plastic are multi-use: they are not disposed of after a single use and the amount of times they are used according to function can range into several hundred uses. Depending on the size and type, the product could also be kept in use for several weeks to multiple months. It is interesting to note that to bring a cosmetic product to market, the formula has to undergo a packaging compatibility test - depending on the ingredients and the function of the product, plastic might be a necessity to safely protect the formula over time and ensure a safe customer experience. For example, glass shampoo bottles intended for use in the shower could be troublesome to manage safely.

Cons of Plastic

Single Use Consumption - Single use packaging is one of the biggest contributing factors to plastic waste across the world. Single use can include any disposable plastic item which is designed to be used only once, often discarded fairly soon after purchase or use.

In the cosmetics industry, single use plastic can take the form of sampling, packaging materials (used during shipments) and spatulas or applicators. Again, 2020 has seen a sharp increase in individual e-commerce shipments and, depending on the state or individual retail procedures, single use spatulas and applicators have either seen a spike or a total halt (for example, if sampling efforts have ceased in store). For treatments or spas, like the medical industry, single use applicators should be the hallmark of sanitation.

Raw materials (ingredients) arrive primarily in plastic bags and plastic drums, with few exceptions - we are not aware of a single ingredient supplier that ships ingredients in glass or wooden barrels. The cost would be staggering and the risk of damage too great. When sourcing our raw materials we take into account the location, packaging materials, certifications and ingredient type (weight) to ensure the lowest carbon footprint possible. However, there are tradeoffs we have to make in order to acquire the safest and most effective ingredients for our formulations.

We have one last observation that we’d like to note in the conversation about single use plastics in light of the ‘zero waste’ movement and heightened pressure for small businesses to make more eco-conscious efforts. Our goal here is to provoke thought, not point a finger at people genuinely trying to do good in the world. It is easy to forget that the finished product is not the only good that needs to be taken into account when making ‘sustainable’ purchases. If we want to assess the environmental impact, we need to look at the entire packaging supply chain: raw material packaging, transport, production, concluding with the finished product.

End-of-Life - A groundbreaking study published in 2017 on the global production, use and fate of plastics, estimated that 30% of all plastics ever produced are currently in use. Between 1950 and 2015, approximately 12% of plastics have been incinerated and 9% have been recycled, and only 10% have been recycled more than once. Around 60% of all plastics ever produced were discarded and are accumulating in landfills or the natural environment.

‘End-of-life’ refers to the destination of the PET product after use which includes the following disposal options: Mechanical or chemical recycling of the plastic, burning (incinerating) the plastic into energy, or burying the plastic in a landfill. Not a single one of these management systems is a perfect solution and there is great need for innovation to prevent waste from heading directly to landfills or accumulating as litter in different ecosystems. To read more about the different types of end-of-life fates for plastic, continue reading within our resources section.

The most ideal solution, in principle, is working towards a circular economy, where plastic is kept in constant use or rotation, as opposed to the current mostly linear economy. The transition to a circular economy offers opportunities to close waste loops for plastic and extends the life of plastic through recycling. At present, the global recycling management system is lacking the fundamental technology to create a circular economy. Again, innovation is necessary to provide the economic systems necessary for this material to be used to its fullest potential.

In Conclusion

We have to abandon perfectionist thinking when it comes to sustainability, but we need to shift our approach to plastic packaging in terms of life cycle assessment. Waste is a product of a throwaway culture that treats plastic as a disposable material rather than a valuable resource to be harnessed. Innovation and accountability for sustainability is necessary along the entire supply chain of a product - starting with the ingredient suppliers, production facilities, brands, transport, retailers, consumers, and concluding with waste management.

We can confidently conclude that we have a lot of work to do in end-of-life management for plastics, even though their production is relatively energy efficient in comparison to other packaging materials like glass and aluminium. Transitioning away from a linear waste economy to a circular economy will be vital to meet the UN definition of a sustainable society: one that meets the needs of the present generation without compromising the ability of future generations to meet their own needs.

Resources

Plastic Pollution. Oxford University and Global Change Data Lab.

Impact Of Plastics Packaging On Life Cycle Energy Consumption & Greenhouse Gas Emissions In The United States And Canada. Substitution Analysis. Franklin Associates, A Division of Eastern Research Group (ERG) © January 2014

"U.S. Life Cycle Inventory Database." (2012). National Renewable Energy Laboratory, 2012. Accessed November 19, 2012:

Single-use Plastics: A Roadmap for Sustainability. United Nations Environment Programme, 2018.

Single-use Plastics. Institute for European Environmental Policy (IEEP). October 2016.

Sustainable Plastics: Environmental Assessments of Biobased, Biodegradable, and Recycled Plastics. Joseph P. Greene. © 2014 by John Wiley & Sons, Inc. ISBN 978-1-118-10481-1 (hardback)

Lifecycle Inventory Of Three Single-serving Soft Drink Containers. Franklin Associates. August 2009.

For more projects: http://www.fal.com/projects.html

Production, use, and fate of all plastics ever made. Roland Geyer, Jenna R. Jambeck, and Kara Lavender Law. Science Advances. ©2017 ;3: e1700782 19 July 2017

Introduction to PET. PET Resin Association (PETRA).

The Future of Petrochemicals. International Energy Agency.

Gomes, Thiago & Visconte, Leila & Pacheco, Elen. (2019). Life Cycle Assessment of Polyethylene Terephthalate Packaging: An Overview. Journal of Polymers and the Environment. 27. 10.1007/s10924-019-01375-5.

WRITTEN BY Josh Rosebrook